Plastic and Metal Machining

| Material available | Steel, aluminum, brass, plastic, organic glass etc. |

| Surface treatment |

Sandblasting, anodizing, electroplating, powder coating, baking varnish etc. |

| Processing |

turning, milling, drilling, wire EDM, welding, casting, forging, assembling, etc. |

| Tolerance | +/-0.001mm or +/- 0.00004″ |

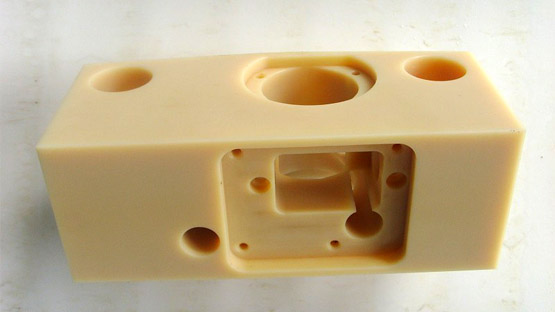

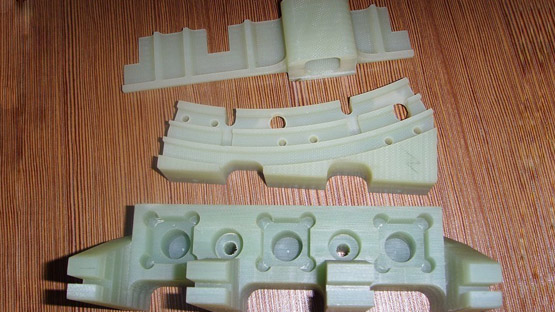

CNC Milling

5 Axis Milling – whether your product requires simultaneous 5 Axis milling or 3+2 indexing, we can handle it. Many parts benefit from significant reduction in setup time and increased accuracy by combining several traditional milling operations into one setup on a 5 Axis mill. We routinely machine parts in 2 operations that would require 10+ setups on a 3 Axis mill. The result is a higher quality product at an economical price.

Horizontal Milling – our palletized horizontal milling cell allows us to machine hundreds of parts unattended and completely automated around the clock. This results in uniform part quality, higher throughput and better value to our customer. Qinuo CNC department can offer very competitive bids on both large volume and small lot production runs because of this investment in technology.

3 & 4 Axis Vertical milling – from complicated 3D-surfaced parts to secondary milling operations on turned parts, our vertical machining centers can handle it all. Quick setups and great accuracy result in high quality parts and great value to our customer. All of our vertical mills are 4th Axis-equipped and can machine all types of material and a wide variety of parts.

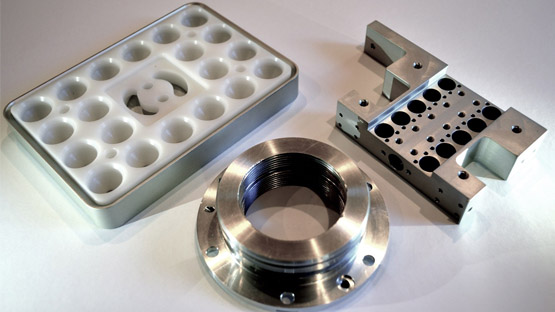

CNC Turning

Multi-task Machining – through the use of multi-tasking lathes, we’re able to perform both turning and milling operations in one setup, often with unattended operation. This results in higher quality parts being produced more quickly than traditional machining methods and offers the best possible value to the customer.

2 Axis Turning – from hard metal to aluminum, our turning centers can efficiently produce high quality parts of all sizes. The combination of our high-precision equipment and machining expertise allows Qinuo CNC department to hold tolerances in the tenths and often machine parts that previously required secondary grinding operations to hold surface finish and diameter tolerances. Our customers benefit from the reduced lead times and lower manufacturing costs.

Bar-fed Turning – bar feeders allow us to feed our lathes with 100+ feet of material at once. This allows the machine to run unattended around the clock. Since the machine never stops the throughput and quality are very high and labor costs are very low, offering our customer the best possible value on simple turned parts.

Assembly

Qinuo CNC department can handle all light assembly, making us a one stop shop. Whether your machined assembly requires threaded inserts, dowel pins or bushings our experienced staff can get it done properly and efficiently.

Engineering

Qinuo CNC department’s expert staff routinely works directly with our customers in the initial product development phases to help design for manufacturing, resulting in better quality and a lower total cost of a machined part. When we receive a new project our programmers develop a manufacturing method, design any associated tooling or fixtures and generate the most efficient and reliable machining programs. We have extensive experience with everything – from airframe components to RF housings, and are continuously exploring the latest industry technology assuring we’re on the cutting edge in the machining industry.

The workers from Qinuo will inspect in their own process, 100% inspection for all dimensions before deliver goods.

English

English  简体中文

简体中文